We have a proven reputation for delivering the highest quality products, with broad and varied sector experience, meeting complex engineering challenges.

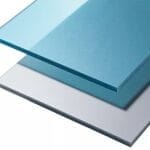

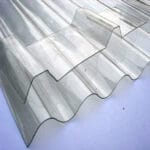

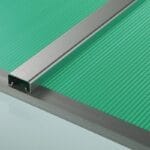

Durapoll GP

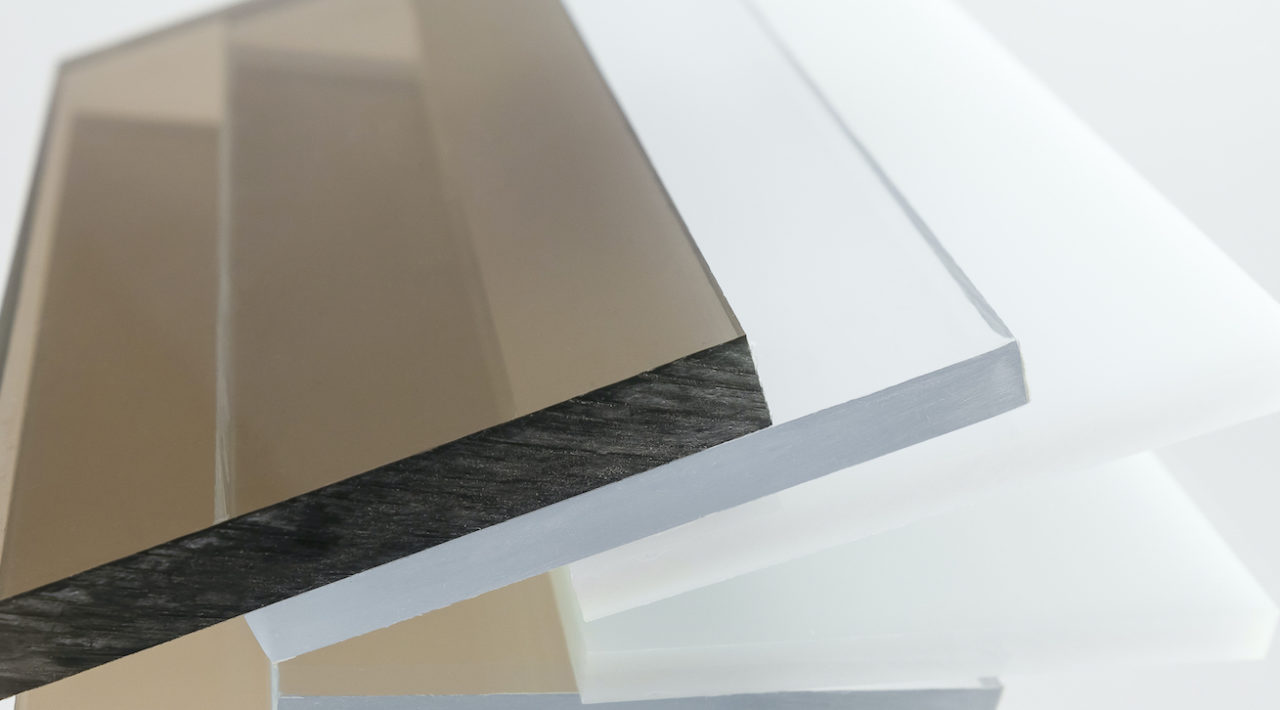

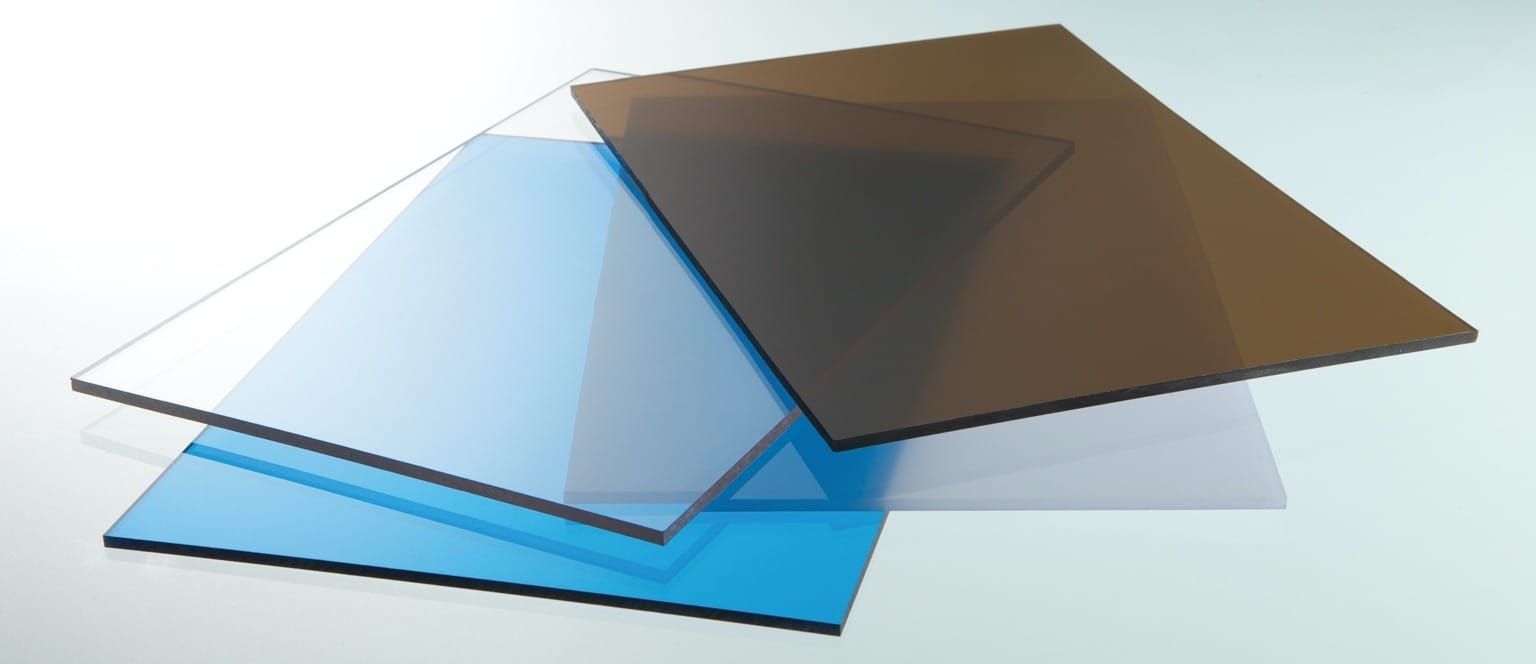

Solid Polycarbonate Sheets

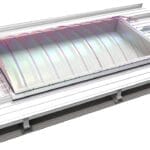

Domer Durapoll

is a polycarbonate solid sheet with extraordinary durability, strength, and heat resistance. Virtually unbreakable and it can be extruded with vibrant opaque colors or transparent and translucent shades and surface treatments.

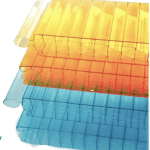

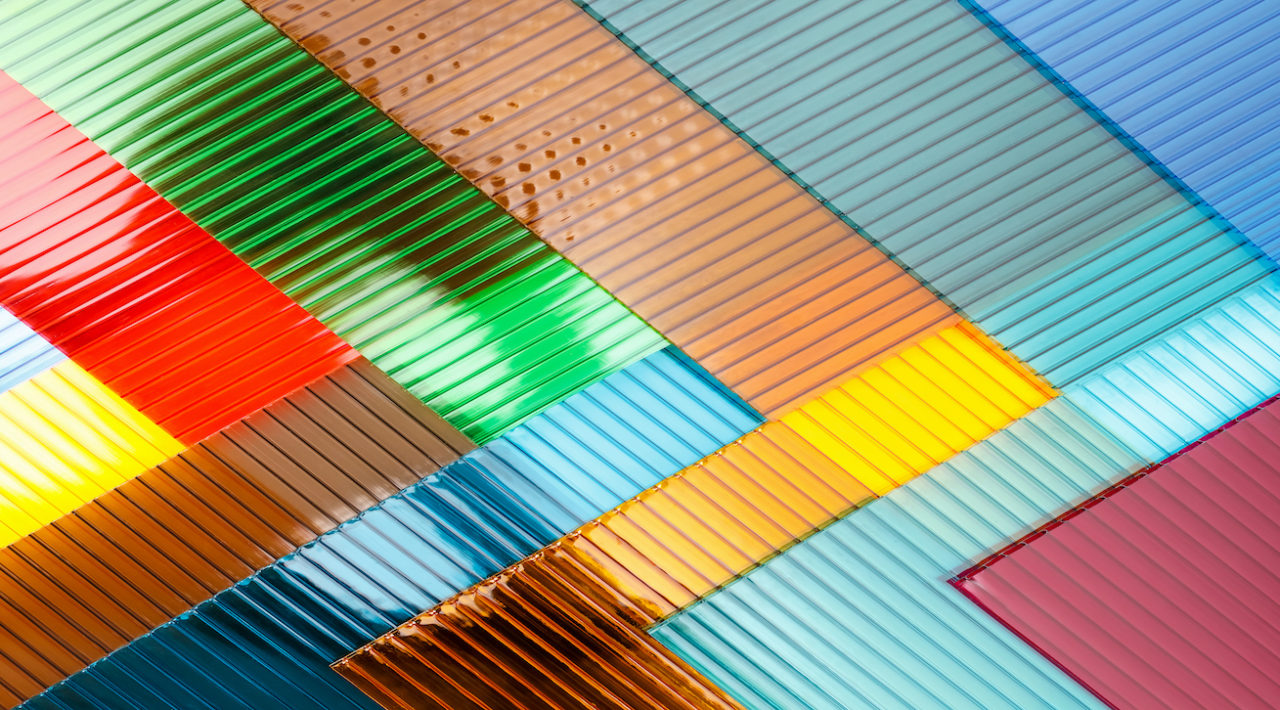

Domer Durapoll polycarbonate sheet is available in a wide range of tints and colors from glass-clear transparent polycarbonate sheets to opaque, and different levels of clarity, light transmission, and light diffusion to meet all your requirements. Domer polycarbonate sheets are also available with one or two sides of UV resistance co-extruded layers to provide an excellent outdoor weathering performance.

Applications:

- Architectural Glazing

- Interior Decoration

- Sound Barriers

- Security Glazing

- Manufacturing

- Windows

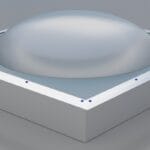

- Skylights

Strength and Durability

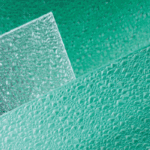

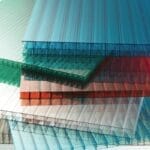

Domer Durapoll polycarbonate sheets provide 200 times more impact resistance than glass with less than half the weight and can be cold bent, fabricated, or thermoformed, making them ideal for construction, industrial, manufacturing, or other applications. Domer Durapoll polycarbonate sheets can be processed with special resins or high-tech coatings for fire resistance, solar control, anti-condensation, or hard-coated polycarbonate sheets. Also available in different textures as embossed, frosted, diamond, or prismatic.

A unique combination of properties in Domer Durapoll polycarbonate solid sheets can be customized, achieving advanced solutions for architectural glazing, interior decorations, sound barriers, partitions, signage, security glazing, manufacturing, and DIY applications.

Product Benefits:

- Lightweight: Only half weight of glass, reducing building weights and saving on delivery and installation costs

- Excellent impact strength: 200 times more impact resistance than glass

- High clarity: Up to 91% light transmission in clear

- Flame retardancy: Self-extinguishing, does not encourage flames

- Excellent print quality and ink adhesion

- Weatherability: Co-extruded UV layer on one or both sides

| Product Name | Description |

|---|---|

| Domer Durapoll GP | Solid polycarbonate sheets for general purpose |

| Domer Durapoll FR A | Fire retardant solid polycarbonate sheets conforming to American Standard E84 Class A |

| Domer Durapoll FR BS | Fire retardant solid polycarbonate sheets conforming to British Standard BS476-7 Class 1 |

| Thickness | Length | Width |

|---|---|---|

| 0.8 - 3.0mm | No Limit | ≤ 2100mm |

| 3.0 - 20mm | No Limit | ≤ 2450mm |

*customized sizes are available subject to minimum order quantity

| Type | Color |

|---|---|

| Opaque | white, navy blue, sky blue, dark green, mint green, yellow, light grey, dark grey, red, brick red, orange |

| Translucent | transparent clear, opal, bluewish, greenish, yellowish, greyish, reddish, orange |

| Finishing | |

|---|---|

| Solar Control | Colors can be customized subject to minimum order quantity |

| Diffused | Colors can be customized subject to minimum order quantity |

| Dotted | Colors can be customized subject to minimum order quantity |

| Embossed | Check Durapoll EM Series for more details |

*Colors and Finishes can be customized subject to minimum order quantity

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Physical | ||||

| Densitiy | D-792 | g/cm3 | 1.2 | |

| Water Absorption | D-570 | 24 hr. @ 23°C | % | 0.15 |

| Mechanical | ||||

| Tensile Strength at break | D-638 | 10 mm/min | Mpa | 65 |

| Elongation at break | D-638 | 10 mm/min | % | >80 |

| Tensile Modulus of Elasticity | D-638 | 1 mm/min | Mpa | 2300 |

| Flexural Modulus | D-790 | 1.3 mm/min | Mpa | 2350 |

| Rockwell Hardness | D-785 | R scale | 125 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Thermal | ||||

| Long Term Service Temperature | °C | |||

| Short Term Service Temperature | °C | |||

| Coefficient of Linear Expansion | D-696 | mm/m°C | 0.065 | |

| Thermal Conductivity | C-177 | W/mK | 0.21 |

| Property | Test Method | Conditions | Units | Value |

|---|---|---|---|---|

| Optical | ||||

| Haze | D-1003 | Clear Sheet | % | <0.5 |

| Light Transmission | D-1003 | Clear Sheet | % | 90% |

| Refractive Index | D-542 | Clear Sheet | 1586 | |

| Yellowness Index | D-1925 | Clear Sheet | <1 |

browse our projects below

& learn more work we has done.

We have a proven reputation for delivering the highest quality products, with broad and varied sector experience, meeting complex engineering challenges.

Community Noise Control

Area

Wall

Suggested product

Durapoll NC

Material

Polycarbonate

Type

Solid Noise Control

Glazed Wall

AREA

Wall

SUGGESTED PRODUCTS

ContiWall, ContiRoof, Durapoll PS, Multipoll, Vivid PS,

MATERIAL

Polycarbonate, GRP

TYPE

Multiwall, Solid, Corrugated

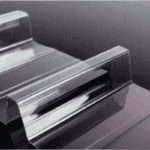

Walkways

AREA

Roof

SUGGESTED PRODUCT

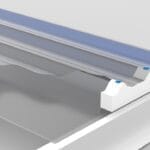

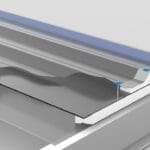

Multipoll, ContiRoof, Durapoll GP, Vivaq PS

MATERIAL

Polycarbonate

Type

Solid, MultiWall, Standing Seam

quality products. inspired design.

unparalleled experience. exemplary service.

Common Questions & Answers

What is polycarbonate?

Polycarbonate (PC) is a thermoplastic material used commonly in engineering due to its high performance, strength, and transparency. They are easily worked, molded, and thermoformed. Owing to their unique features, polycarbonates suit many applications.

Why polycarbonate is often used in construction?

Polycarbonate is often used in construction due to its transparency, lightweight, high impact resistance, and excellent insulation both sound and heat. Available as a flat sheet, dome, panel system, or corrugated sheet, polycarbonate has a wide range of roofing and glazing applications used in projects such as airports, stadiums, warehouses, retail malls, and greenhouses.

What are the benefits of daylight?

Daylight is always associated with improved mood, enhanced morale, and less fatigue. Studies suggest that environments with natural light have a direct impact on increasing the productivity and satisfaction of students and employees. Moreover, introducing daylight into your building will reduce the amount of artificial light decreasing your electricity cost from 15 to 40 percent.

What are the advantages of polycarbonate against the glass?

Polycarbonate sheets have 200 times more impact resistance than glass, being virtually unbreakable while weighing half of the weight. Multiwall sheets are more than 85% lighter than glass having up to 60% better heat insulation hence allowing the reduction of the structural requirements of buildings.

Polycarbonate will never shatter, and it is weather-resistant due to its co-extruded UV protection layer.

Polycarbonate offers excellent properties compared to glass in life expectancy, impact-resistant, lightweight, heat insulation, and maneuvering.

Goal

We strive to build a better community and make a difference in the world