Curtain wall system built for modern architecture

Curtain wall system built for modern architecture Curtain Wall Systems in Construction: Modern Curtain Wall Architecture

Curtain walls are one of the defining features of modern architecture, combining form, function, and performance in a way that traditional building envelopes cannot. They are more than just cladding systems, they are engineered façades that influence a building’s energy consumption, safety, and aesthetic presence.

For architects, curtain walls open creative possibilities, allowing expansive transparent or translucent façades without the structural limits of masonry. For engineers, they represent carefully calibrated systems designed to withstand wind loads, thermal movement, water infiltration, and seismic activity while remaining cost-efficient and sustainable.

Wild West excitement awaits! Spin the reels of Wanted Dead or a Wild for massive casino action. Chase high volatility wins and epic bonus rounds at wanteddeadorwildgame.com. The ultimate gambling adventure is just a click away!

But what exactly is a curtain wall in construction, and why are polycarbonate systems such as Domer ContiWall and Domer ContiRoof transforming how we think about façade design?

Definition of a Curtain Wall

A curtain wall is a lightweight, non-loadbearing façade system that attaches to the structural frame of a building. Its primary role is to protect against environmental conditions while giving architects flexibility to design façades that are transparent, translucent, or opaque.

Unlike structural walls, curtain walls do not carry floor or roof loads. Instead, they:

- Transfer wind and seismic forces back to the primary structure

- Provide barriers against air and water infiltration

- Control thermal performance to reduce energy consumption

- Enhance building aesthetics and visibility

Historical Development of Curtain Wall Systems

From Masonry to Modernism

Early buildings relied on thick stone or brick walls that provided both structure and enclosure. The introduction of steel frameworks in the late 19th century allowed walls to become independent from loadbearing functions, paving the way for glass façades.

The Rise of Glass and Aluminum

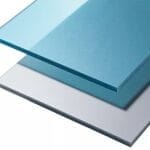

By the mid-20th century, aluminum-framed glass curtain walls became standard in high-rise and commercial buildings. These systems embodied modernist ideals of openness but came with challenges such as weight, thermal inefficiency, and fragility.

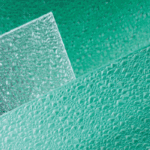

The Polycarbonate Evolution

Today, sustainability and performance drive material innovation. Polycarbonate and advanced composites, such as Domer ContiWall, are lighter, more durable, and far more energy-efficient than conventional glass systems, redefining curtain wall architecture.

Types of Curtain Wall Systems

Stick Curtain Wall Systems

- Constructed piece by piece on-site

- Allow flexibility for complex shapes and custom geometries

- Require more installation time and skilled labor

Unitized Curtain Wall Systems

- Prefabricated modules manufactured in controlled environments

- Faster installation, greater precision, and better quality control

- Well-suited for repetitive façades and large-scale projects

For architects, stick systems provide design freedom, while unitized systems offer speed and reliability. Engineers often evaluate both depending on project timeline and structural constraints.

Curtain Wall Architecture: Key Performance Drivers

Curtain walls are not simply aesthetic elements, they are engineered systems that address multiple performance criteria:

- Structural Loads: Must resist wind suction, deflection, and seismic stresses

- Thermal Efficiency: Target low U-values to reduce HVAC costs

- Daylighting & Glare Control: Balance natural light with occupant comfort

- Acoustic Protection: Block external noise in urban environments

- Fire Resistance: Meet international standards such as EN 13501-1, ASTM E84, and BS476

- Water & Air Tightness: Prevent leaks under extreme weather conditions

- Maintainability: Enable cleaning and replacement without major disruption

This is why curtain walling is central to both architectural design and engineering performance.

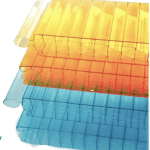

Advantages of Polycarbonate Curtain Wall

Traditional glass curtain walls are visually striking but heavy, costly, and less efficient thermally. Polycarbonate curtain wall systems provide a new set of benefits:

- Lightweight: Up to 50% lighter than glass, reducing structural demand

- High Impact Resistance: Resists hail, debris, and accidental impact

- Thermal Insulation: Multiwall construction provides excellent U-values

- Daylight Diffusion: Soft, glare-free lighting for improved interior comfort

- UV Stability: Co-extruded UV protection ensures long service life

- Ease of Installation: Faster, safer, and lower cost compared to glass

- Design Versatility: Can be curved, profiled, or integrated with steel cladding

For architects, polycarbonate expands design options. For engineers, it delivers practical performance improvements and cost savings.

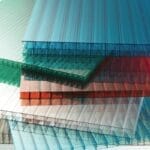

Domer ContiWall: A Polycarbonate Façade Solution

The Domer ContiWall system represents the next generation of curtain wall architecture. Unlike generic panels, it is engineered specifically to integrate with corrugated steel cladding systems used in industrial and commercial buildings.

Key benefits include:

- Precision Fit: CNC molds ensure exact profile alignment

- Superior Sealing: Overlap joints prevent dust and water infiltration

- Daylighting Efficiency: Reduces reliance on artificial lighting by up to 50%

- Durability: UV-protected polycarbonate ensures long-term clarity and performance

- Safety & Compliance: Meets international fire and performance standards

For industrial warehouses, logistics centers, and commercial buildings, ContiWall provides an energy-efficient and architecturally modern façade system.

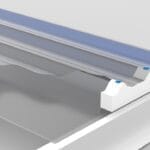

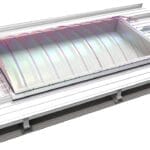

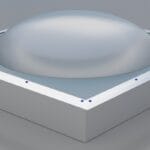

Domer ContiRoof: Completing the Envelope

Curtain walls and roofs must work together to create a unified envelope. The Domer ContiRoof system complements façades with large-span skylight solutions.

Benefits include:

- Seamless Integration: Roof-to-wall continuity for architectural cohesion

- Uniform Daylight: Even distribution across large interior spaces

- Energy Performance: Reduces artificial lighting and HVAC demand

- Longevity: UV-stabilized polycarbonate with resistance to yellowing and weathering

When combined, ContiWall and ContiRoof provide architects and engineers with a holistic solution for façade and roofing performance.

Comparative Performance: Glass vs. Polycarbonate

| Factor | Glass Curtain Wall | Polycarbonate Curtain Wall (e.g., Domer ContiWall) |

|---|---|---|

| Weight | Heavy; increases structural demand | Lightweight; reduces frame loads |

| Impact Resistance | Brittle; prone to shattering | Extremely tough; resists hail and debris |

| Insulation | Limited; requires coatings | Excellent with multiwall panels |

| Daylighting | Transparent but prone to glare | Diffused, glare-free light |

| Installation | Heavy equipment required | Faster and simpler |

| Cost | High material + structural cost | Lower overall lifecycle cost |

Applications of Curtain Wall Systems

Curtain wall systems are applied across multiple building types:

Warehouses and Logistics Hubs

Translucent curtain walls reduce reliance on artificial lighting, cutting operational costs.

Manufacturing Plants

Durable façades resist impact and can be protected against chemical exposure.

Airports and Transport Hubs

Large curtain walls provide openness while meeting safety and performance standards.

Commercial Complexes

Modern façades improve aesthetics, brand presence, and energy performance.

Sports and Event Venues

Balance daylight, acoustics, and safety in high-capacity spaces.

Sustainability and Green Building

Modern architecture demands sustainable solutions. Polycarbonate curtain walls contribute by:

- Lowering operational energy demand through daylight harvesting

- Reducing embodied carbon due to lighter weight structures

- Supporting LEED/BREEAM credits for energy and daylighting

- Offering long service life with minimal maintenance

For developers, these systems align with global sustainability targets and reduce lifecycle costs.

Design Considerations for Architects and Engineers

When specifying curtain walls, professionals must assess:

- Building Orientation: Optimize daylight without overheating

- Climate Conditions: Choose materials based on wind, humidity, and UV exposure

- Fire Codes: Ensure compliance with local and international regulations

- Integration with Cladding: Match profiles for watertight sealing

- Maintenance Access: Plan for façade cleaning and component replacement

- Aesthetic Goals: Balance transparency, translucency, and branding

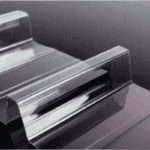

Curtain Wall Installation Process

Installing a curtain wall system requires precision engineering and skilled coordination between architects, engineers, and contractors. The installation process varies depending on whether the project uses a stick-built curtain wall or a unitized curtain wall system, but the core steps remain similar.

1. Structural Preparation

The building’s primary structure must be aligned and reinforced to handle wind loads and the weight of the curtain walling system. Anchor points and brackets are installed on beams and columns to receive the façade.

2. Frame Assembly

For stick systems, mullions (vertical members) and transoms (horizontal members) are assembled piece by piece on-site. For unitized systems, pre-manufactured modules arrive ready to be lifted into place, reducing site labor.

3. Panel Installation

Curtain wall infill panels (glass, polycarbonate, or composite materials) are fitted within the frame. With polycarbonate, panels are often lighter, making installation faster and safer compared to glass.

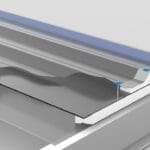

4. Sealing and Weatherproofing

Joints are sealed with gaskets, silicone, or overlapping profiles. Proper sealing ensures the system’s resistance against water infiltration, thermal bridging, and air leakage.

5. Finishing and Inspection

The façade undergoes final alignment checks, pressure tests, and thermal performance validation to comply with standards such as ASTM, EN, or BS.

When designed and installed correctly, a curtain wall can last decades with minimal maintenance, making it one of the most durable envelope solutions available.

Real-World Applications of Curtain Walls

While curtain walls are often associated with iconic skyscrapers, their use extends far beyond high-rise construction. Below are real-world examples that highlight their versatility:

Industrial Warehouses

Warehouses often require translucent curtain walling to maximize daylight while reducing artificial lighting costs. Systems like Domer ContiWall allow facilities to lower energy bills by up to 50%.

Airports and Terminals

Airports rely on large-span curtain wall façades for transparency and passenger visibility. The balance of natural light, fire safety, and acoustic insulation is critical. Polycarbonate panels provide glare-free comfort while resisting heavy foot traffic conditions.

Stadiums and Arenas

Sports venues use curtain wall systems to create dramatic entrances and ensure safe crowd management. Polycarbonate walls resist impact from balls, equipment, and extreme weather, while still delivering striking aesthetics.

Commercial Complexes

Office towers, retail malls, and mixed-use buildings benefit from the modern appeal of curtain wall architecture. Polycarbonate provides energy efficiency while reinforcing brand image through unique façade designs.

These case studies show that curtain walling systems are not limited to aesthetics but contribute significantly to operational performance, sustainability, and user experience.

Future Trends in Curtain Wall Architecture

Curtain walls continue to evolve as building technology advances. Several key trends are shaping the future of curtain wall systems:

1. Smart Façades

Integration of IoT sensors allows curtain walls to react to climate conditions, adjusting ventilation, shading, or transparency in real time.

2. Hybrid Materials

Next-generation curtain walling combines polycarbonate, ETFE foils, and advanced composites with traditional aluminum frames for lighter, stronger, and more sustainable façades.

3. Net-Zero Buildings

Curtain walls are being engineered to contribute directly to net-zero energy targets by maximizing daylight harvesting, integrating photovoltaics, and reducing thermal loads.

4. Circular Construction

Sustainability goals drive a shift toward recyclable curtain wall materials. Polycarbonate panels, unlike glass, can be reclaimed and repurposed with lower environmental impact.

5. Biophilic Design

Future curtain wall systems will increasingly integrate greenery, vertical gardens, and natural ventilation to connect occupants with nature.

These innovations show how curtain wall architecture will remain a cornerstone of modern building design, not just as an enclosure, but as a living, adaptive system.

Frequently Asked Questions

What is a curtain wall in construction?

A curtain wall is a non-loadbearing façade system attached to a structural frame that protects against wind, water, and environmental conditions while allowing aesthetic freedom.

What is curtain wall architecture?

It refers to the design of non-structural façades that balance aesthetics with performance, including daylighting, thermal control, and weather protection.

Is polycarbonate reliable for curtain walls?

Yes. Systems like Domer ContiWall are engineered for impact resistance, UV stability, fire compliance, and energy efficiency.

What are the advantages of polycarbonate over glass?

Polycarbonate is lighter, stronger, more insulating, and less expensive while providing glare-free daylight.

Where are curtain wall systems used?

They are common in warehouses, factories, commercial complexes, airports, and public infrastructure where energy efficiency and aesthetics are critical.

Conclusion

Curtain walls are no longer just an architectural statement, they are engineered systems that define how modern buildings perform. From energy savings to durability, they shape the user experience and long-term sustainability of projects.

With innovations like Domer ContiWall polycarbonate façades and Domer ContiRoof skylight systems, architects and engineers gain solutions that are lighter, stronger, and more efficient than traditional glass walls.

So, when asking what is a curtain wall in construction, the answer is clear: it is a high-performance façade system that protects, inspires, and defines the future of architecture.